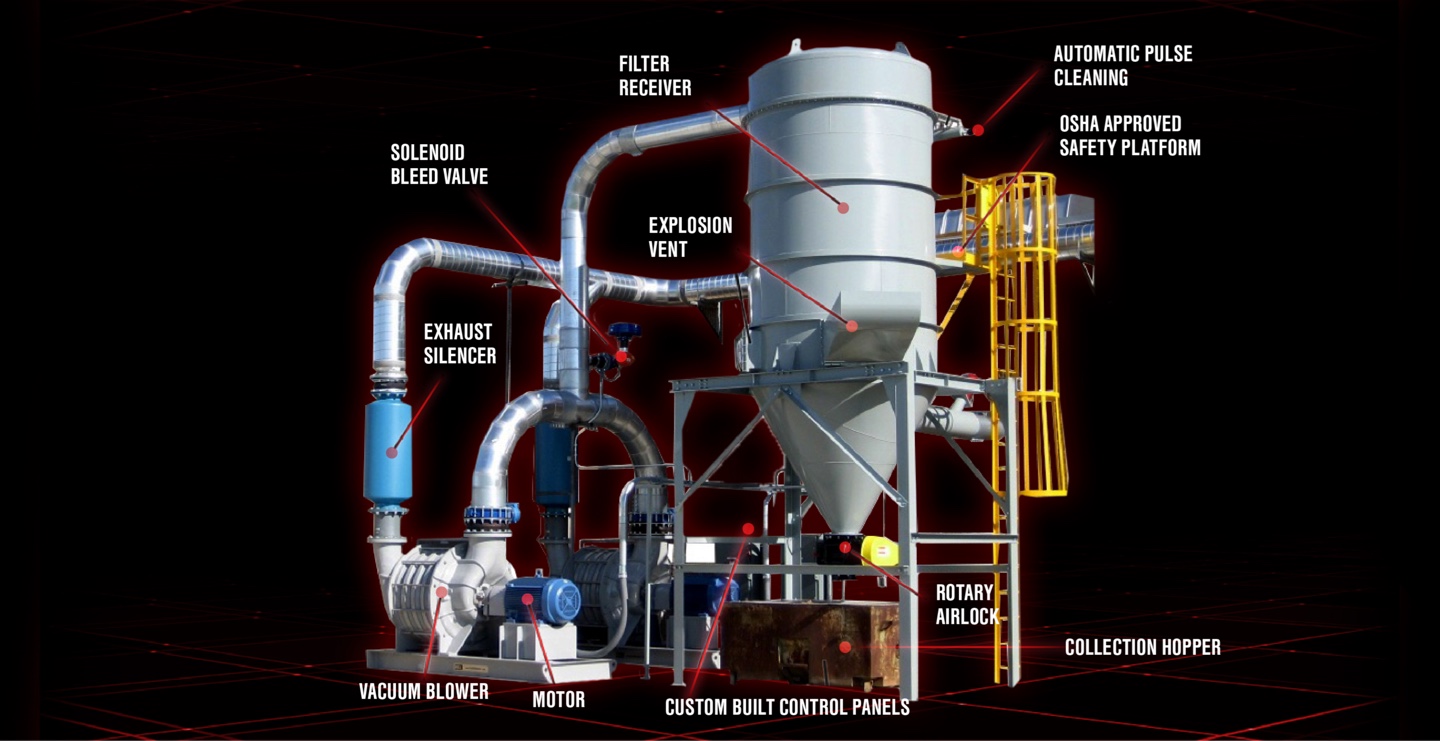

Custom Industrial Central Vacuum Systems

Features of Custom Vacuum Systems

At American Vacuum Company, we specialize in tailoring vacuum systems to fit the unique demands of your operation. By taking into account critical factors, we ensure that each system is optimized for performance, efficiency, and durability.

Key Factors Considered in System Design:

- Type of Plant or Environment

- The specific industry or facility type, such as manufacturing plants, warehouses, food processing facilities, or cleanrooms, plays a vital role in determining the vacuum system's design and material requirements.

- Product or Operation

- The vacuum system’s design is influenced by the type of materials being handled, whether it’s fine dust, debris, liquids, or heavier substances like metal shavings or bulk powders.

- Cleaning Area

- The approximate size of the area to be cleaned helps define the vacuum system’s capacity and piping layout to ensure efficient coverage.

- Cleaning Frequency

- Whether the system will be used intermittently or continuously impacts the choice of vacuum producer, filtration systems, and other components.

- Volume of Materials Collected

- Understanding the daily volume of materials (measured in cubic feet or pounds) ensures the system is built to handle the workload without compromising performance or longevity.

Customization Options

American Vacuum can create both single- and multi-operator vacuum systems, each custom-sized and designed to meet your exact needs. Our custom designs offer:

- Material Options: Systems can be built using materials such as galvanized zinc for enhanced durability and corrosion resistance.

- Sealing and Connection Features: Join sealing and shrink sleeves ensure a secure, leak-free operation throughout the piping network.

- Strategic Inlet Valve Placement: Valves are positioned exactly where they are needed for optimal convenience and efficiency in your workspace.

With these tailored features, our vacuum systems not only meet but exceed the demands of your specific application, helping you maintain a cleaner, safer, and more productive environment.

Partner with American Vacuum

By prioritizing customization and quality, we deliver solutions that integrate seamlessly into your operations, ensuring reliability and consistent performance. Contact us today to discuss your project requirements and explore how we can design the perfect vacuum system for your facility.

Exhaust Silencer

Silencers are designed to quite the discharge air from the vacuum exhauster. We offer different silencers for the different types of vacuum pumps that we sell.

Solenoid Bleed Valve

A solenoid bleed valve is an automatic valve that opens and closes to keep a vacuum pump out of surge. Solenoid valves, modulating butterfly valves and relief valves can be used depending on the machine.

Explosion Vent

Explosion vents are an integral component of a modern day vacuum system. Our vents are sized based on the Kst and Pmax value provided by the customer. Our vents can be configured for indoor or outdoor use. We also use the latest in inlet and outlet fire suppression systems.

Vacuum Blower

Vacuum Baghouse

Control Panel

American Vacuum custom builds all of our control panels. Each vacuum system control panel is tailored to the vacuum systems unique specifications. From 3 phase controls such as the motor and rotary air lock to single phase and low voltage controls, our control panels can handle them all.

Rotary Airlock

Rotary airlocks or flap gate valves help keep the vacuum system running smoothly. Not only do the valves move material from the filter baghouse into the disposable vessel, but they keep you in NPFA compliance by removing your potential fuel source as quick as possible.

Safety Platform

Each baghouse that we build can be equipped with an OSHA compliant service platform. These platforms allow for easy access to the filter bags & baghouse control systems mounted on the filter receivers.

Automatic Pulse Jet Cleaning

All of our central vacuum systems are equipped with a automatic filter cleaning system. By Utilizing either photohelic or magnahelic controls our systems dictate how often the filters are being cleaned to ensure longer life for the filters.

Collection Hopper

American Vacuum can configure our baghouses to accommodate most types of collection hoppers. From Super sacs and 55 gallon drums to roll off dumpsters our systems can be tailored to most hoppers.